Product Description:

Container Corner Casting is a crucial part of the container, made from strong materials like cast iron or other durable metals. It is designed to withstand the pressures of stacking, lifting, and other physical impacts that containers face during transportation. The Container Corner Casting helps support the four corners of the container, making it a key component for ensuring the container's stability and structural integrity during use.

Uses:

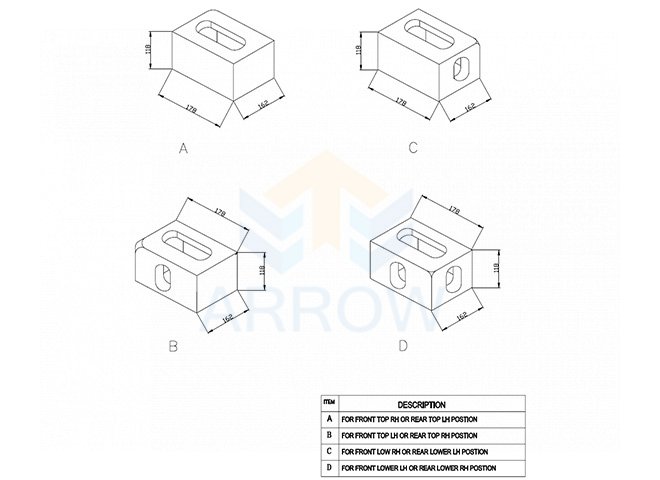

The Container Corner Casting is used at the four corners of a container. Typically, a container needs 8 corner castings: 2 for the front right (TR), 2 for the front left (TL), 2 for the back right (BR), and 2 for the back left (BL). These Container Corner Castings are essential for connecting the container to lifting equipment like cranes and forklifts. They ensure that the container can be safely lifted, moved, and stacked during loading and unloading, whether by sea, land, or rail. Without these corner castings, the container would not be able to maintain the stability required for safe and efficient transport.

Functionality:

The main function of Container Corner Castings is to provide strong connection points between the container and lifting equipment. They help prevent the container from shifting or getting damaged during lifting, stacking, or moving. Especially in high-stress stacking conditions, Container Corner Castings ensure the container remains stable and intact. These castings also ensure the container can withstand harsh transport conditions, keeping goods secure and improving transport efficiency.

Using high-quality Container Corner Castings ensures that containers are more stable and durable during global transport, enabling safe handling across different modes of transportation.

If you want to learn more information,please contact eva@containerplywood.com